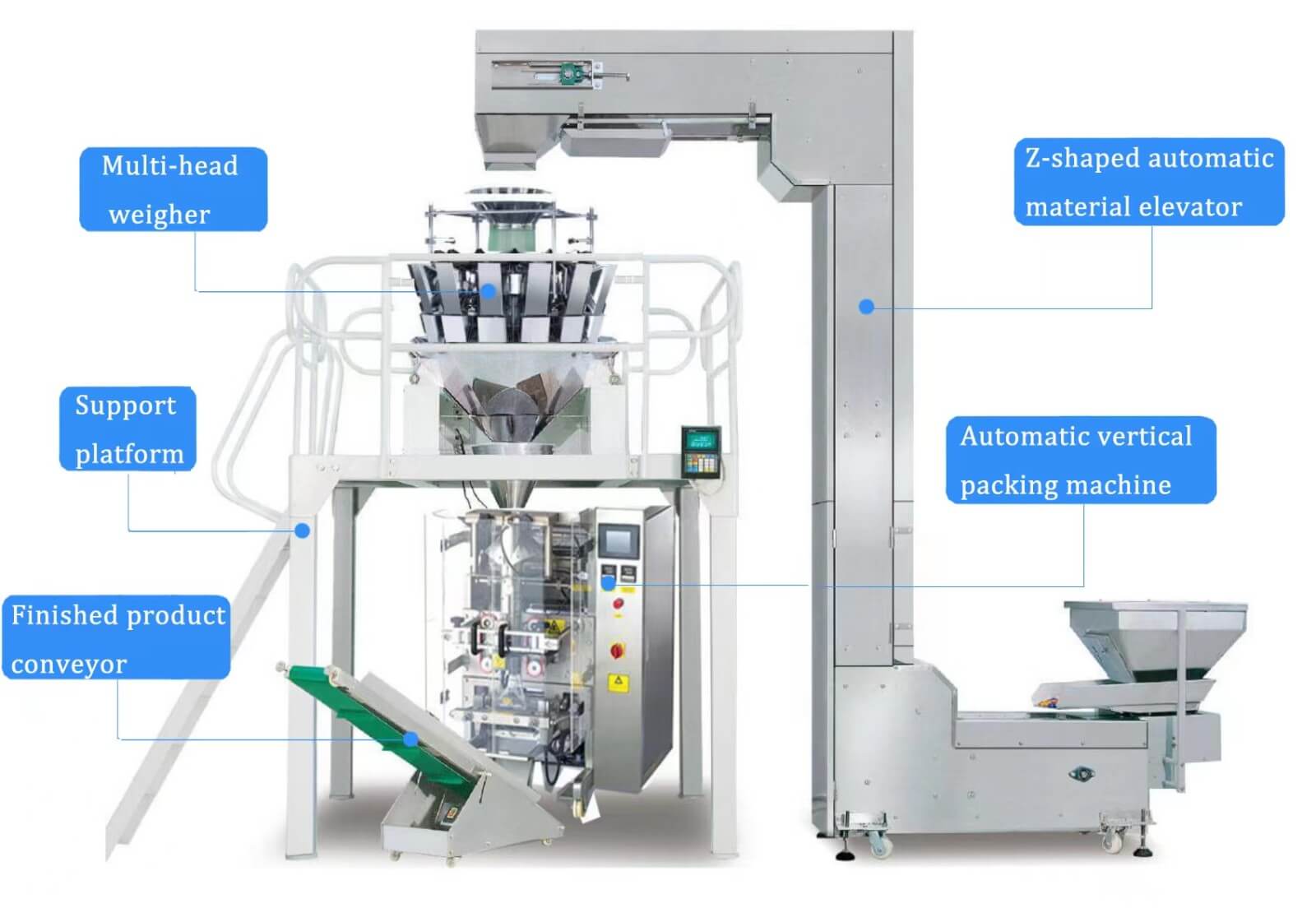

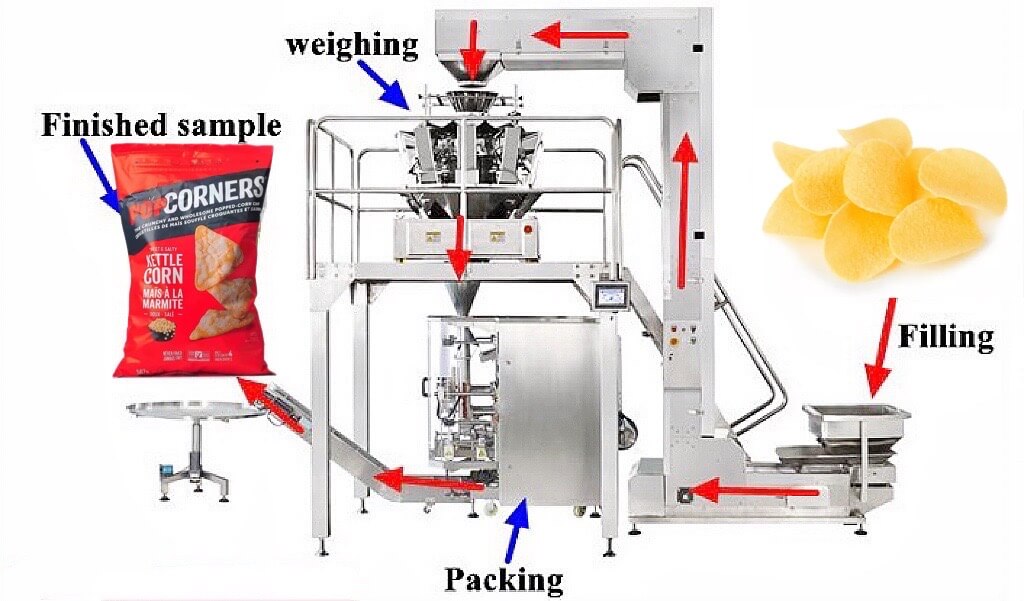

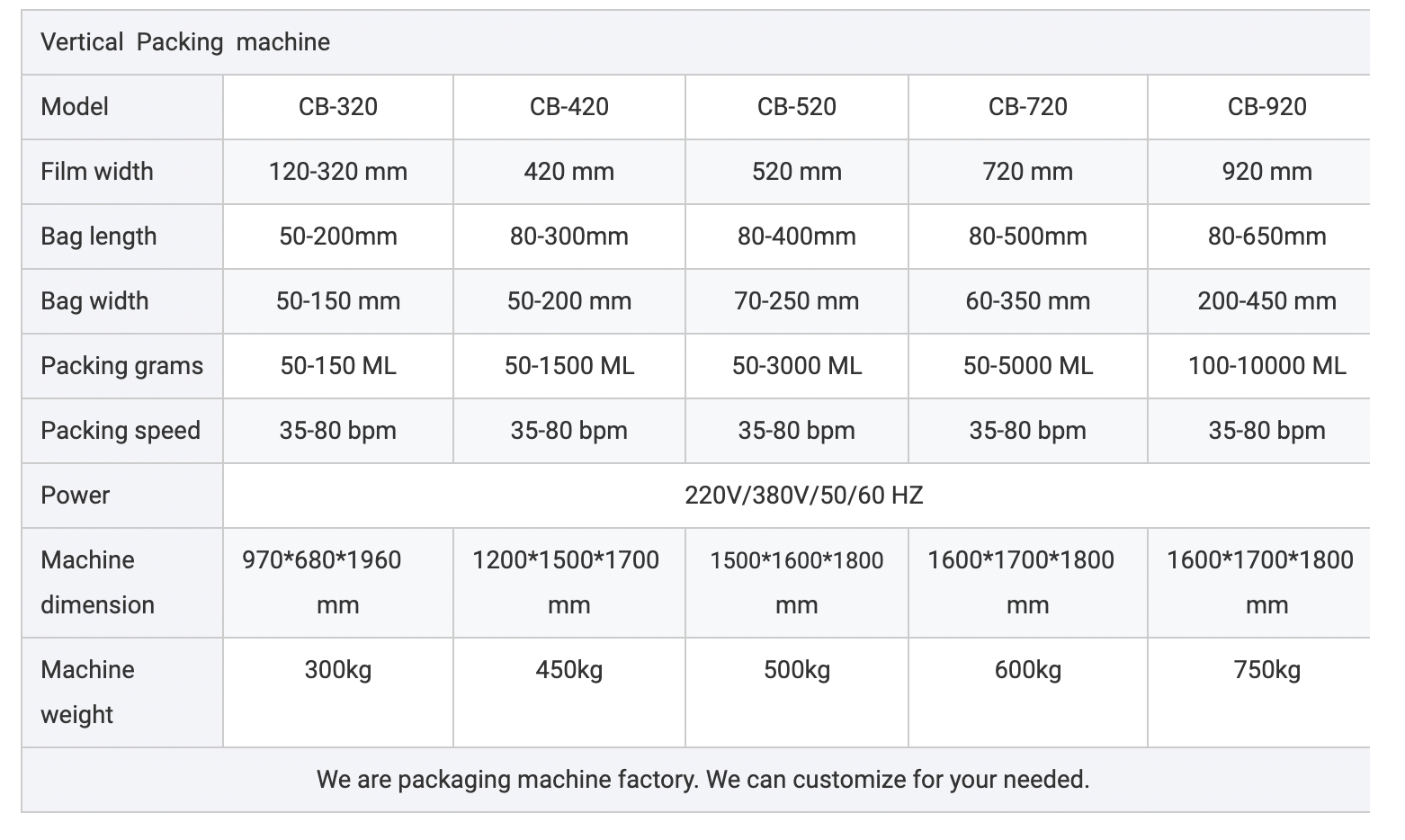

Chips Packing Machine

Our chips packing machine has 20 years of research and development and manufacturing experience in China. Applicable to bulk strip-shaped materials such as: pasta, chips, nuts, candy automatic weighing and packaging. Fully automatic and high-precision weighing and high-speed packaging, controlled by a highly intelligent system, with strong stability and stainless steel material meeting food grade standards. The 8000 square meter production and manufacturing workshop has a R&D technical team of over 20 people and over 100 employees. This chips packing machine have CE and ISO9001 certifications, over 30 national technology patents, and have led the development of Chinese national technical standards for noodle packaging.Products are sold to countries such as the United States, North America, South America, Africa, and Europe.

Details

Chips Packing Machine

1,Requirement for high precision measurement and fragile packaging bulk goods, such as: puffed food, crispy rice, fruit chips, sweets, pistachio, apple slices, dumpling, chocolate, balloon, rubber, Screw the Nut hardware item, medicines etc.

2,Highly sensitive weighing sensor, with the highest measurement accuracy up to + / - 0.5g.

3, Anti-acid-base 304 stainless steel plate, meeting the standards of food SC certification and drug GMC.

4, The standard procedure is to make sheet metal parts by hand. The mounting error is as small as 1mm

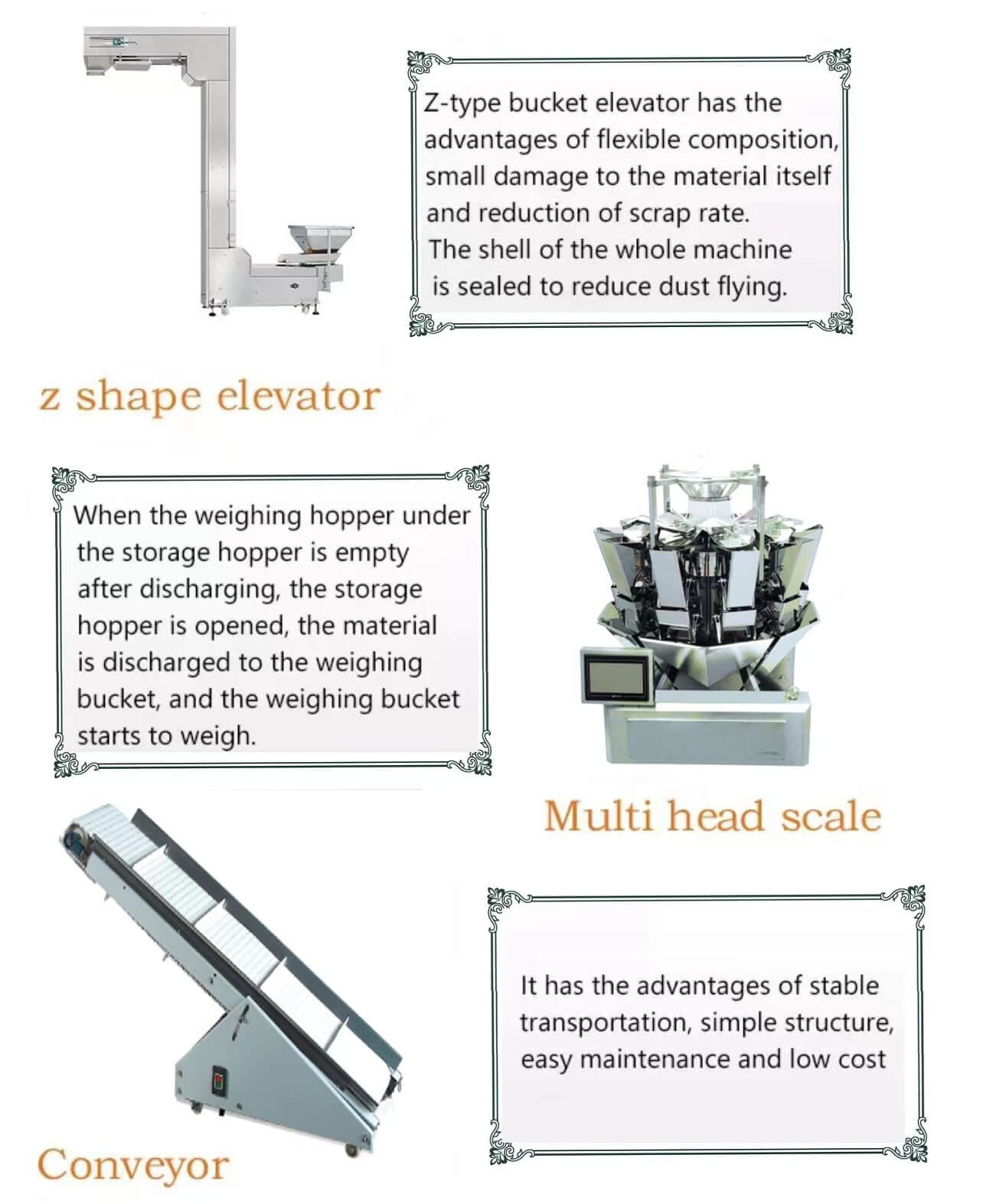

5, Automatic bayonet weighing hopper, storage hopper, main vibration and wire vibration without screw fixation.Simple disassembly and convenient cleaning

6, 10 sets of customized storage data, which can store 10 sets of commonly used parameters. When it is necessary to switch parameters, it is convenient and fast to switch with one key

7,There are 50 kinds of basic parameters of products with different attributes and shapes in the database. Only the same or should be selected when weighing

Similar material pictures, and then set the weight to complete the measurement part.Easy to understand.

8,Real-time monitoring screen can instantly check the weight of the blanking combination, check the stability and error of the weight.

9,The equipment is mainly calculated by mathematical combination. Many qualified combinations are made from multiple weighing hopper, and then the most similar combination is selected from them.

10, As many as dozens of languages can be switched at will.

11, You can customize the concavo-convex pattern plate, rotary weight, no material storage, non-stick material.One said multi-purpose, can achieve the same type of product diversified packaging.

Optional Device

1. Printer(ink jet, Thermal transfer, color ribbon date printer)

2. Nitrogen device

3. Labeling device