Nut Packaging Machines

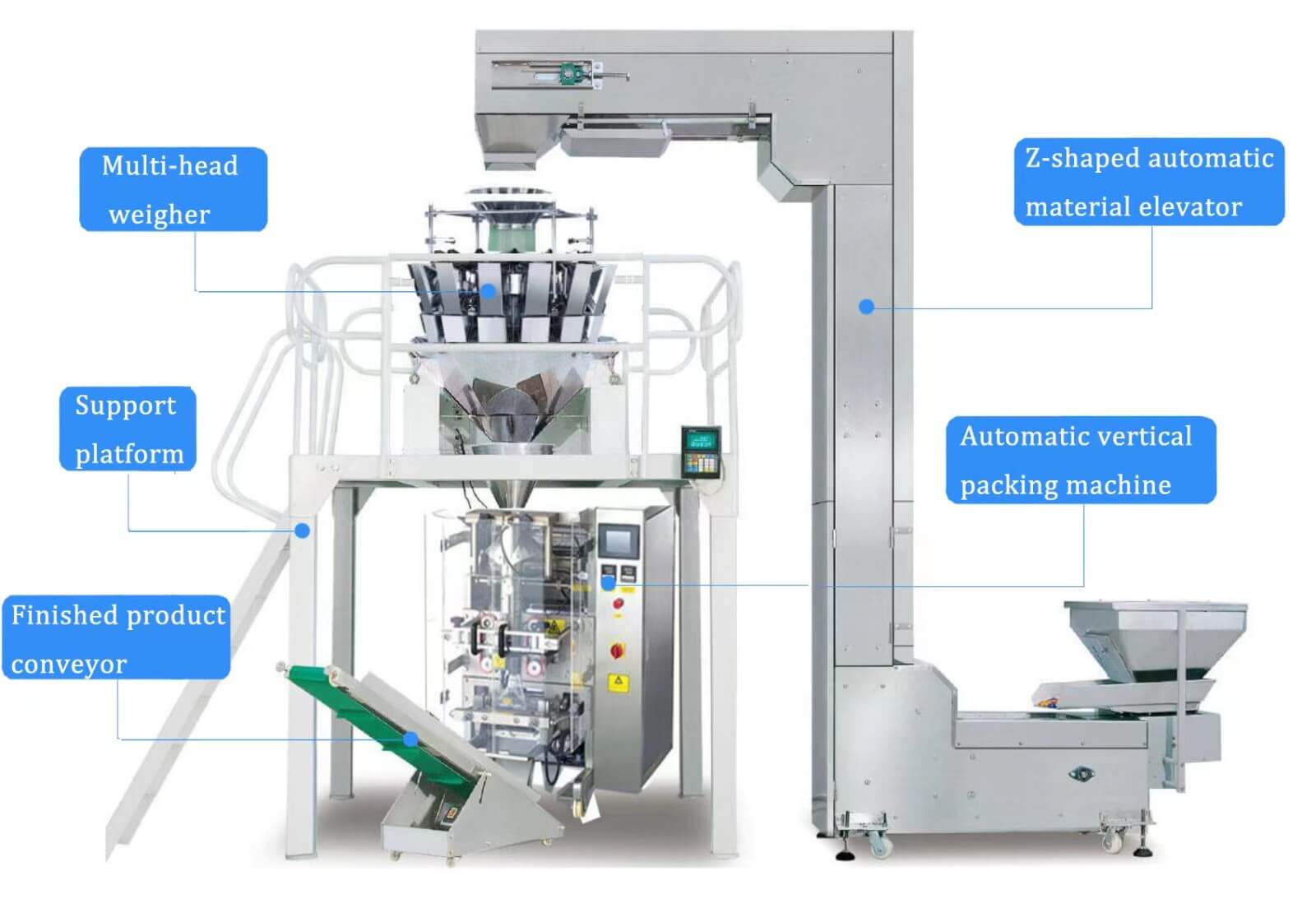

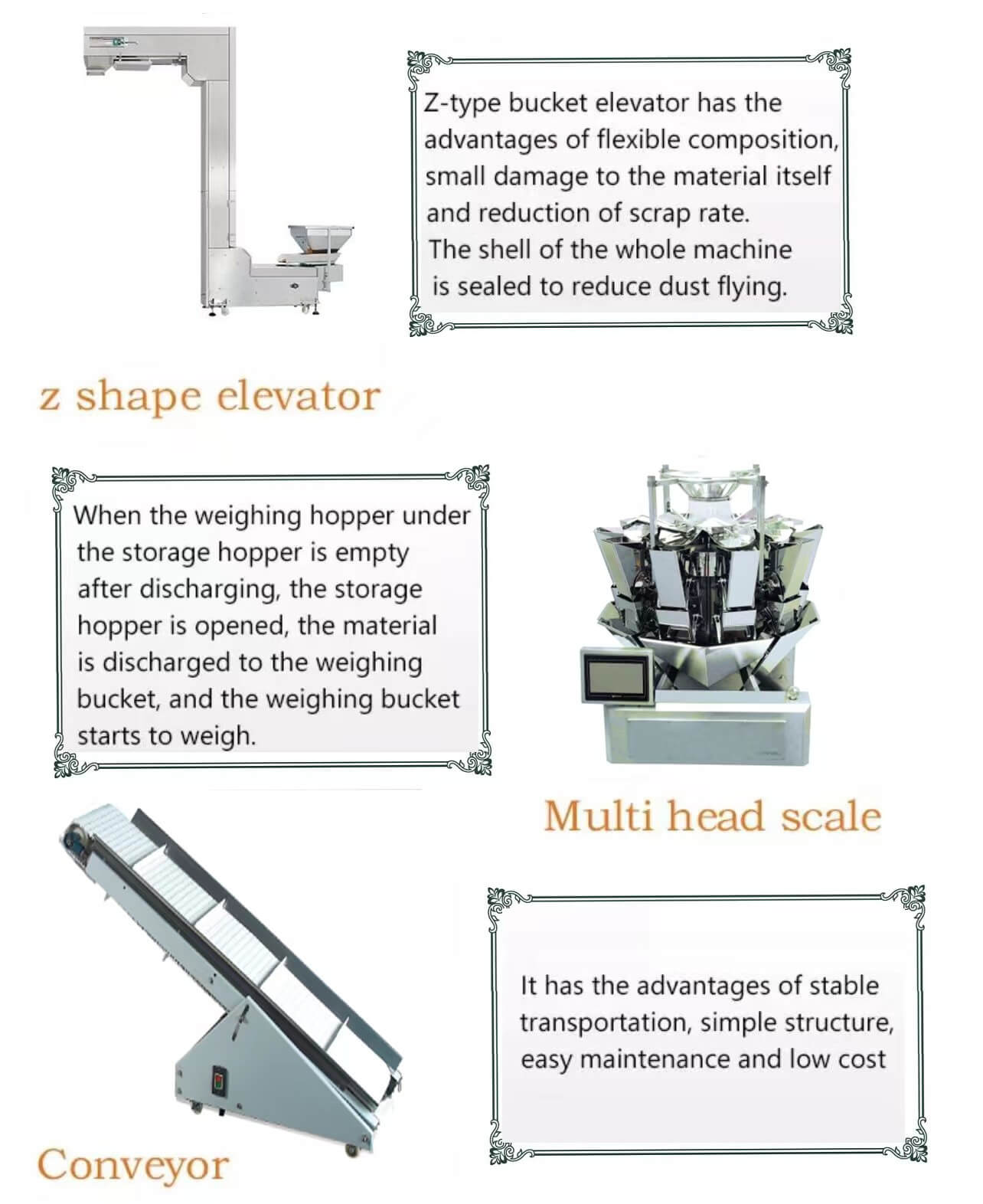

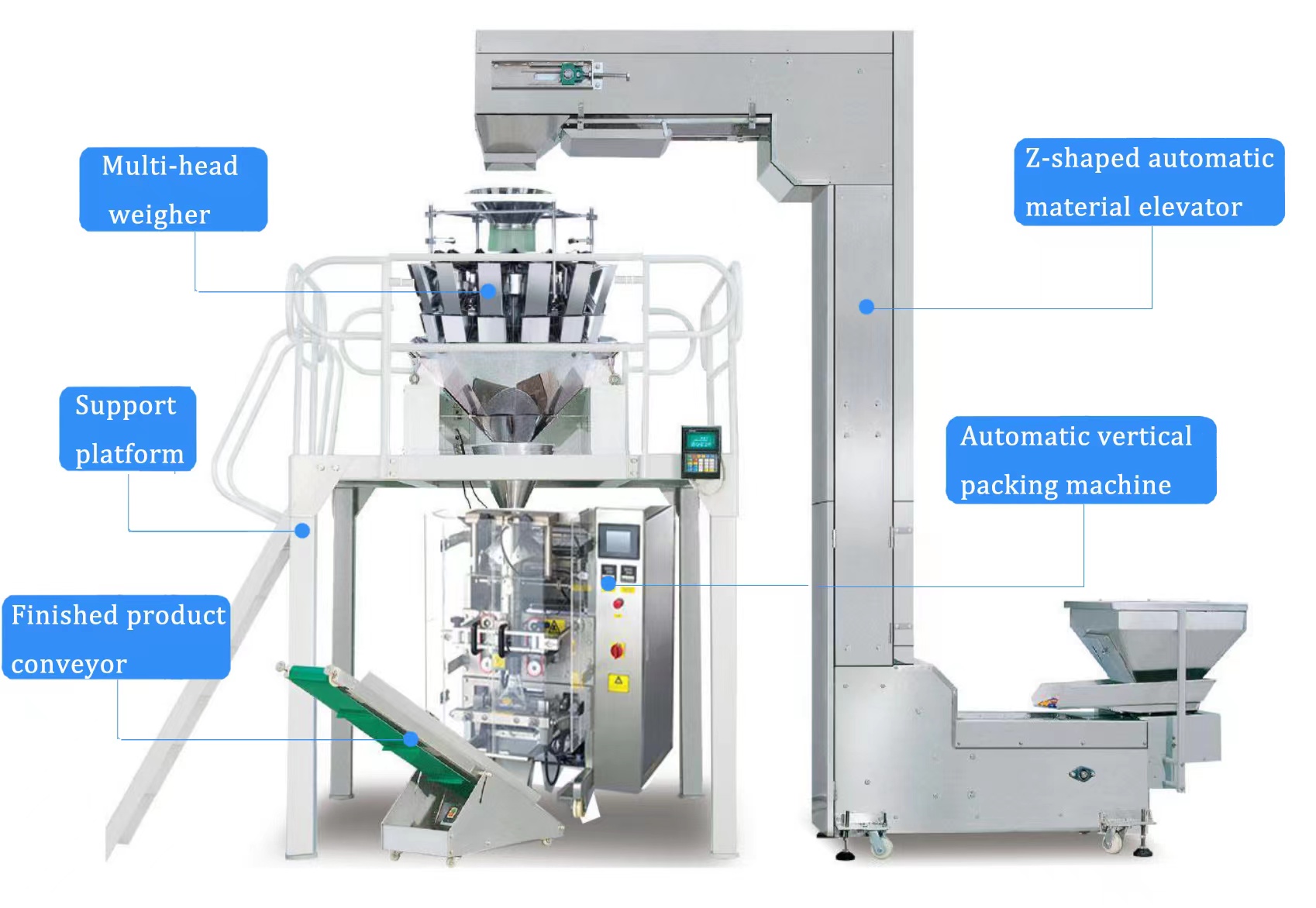

Hfirst Food packaging machine has 20 years of research and development and manufacturing experience in China. Applicable to bulk strip-shaped materials such as: nuts, dry vegetables, pasta, grain,candy automatic weighing and packaging. Fully automatic and high-precision weighing and high-speed packaging, controlled by a highly intelligent system, with strong stability and stainless steel material meeting food grade standards. The automatic bag weighing and filling machine uses high-precision, high-standard special sensors, more accurate measurement. It can automatically pause when there is no material to make the weighing more stable. The amplitude of each line can be adjusted independently during operation to make the feeding more even. The mixed nuts packing machine with multiple language, easy to operate, and meet the needs of customers in different countries.

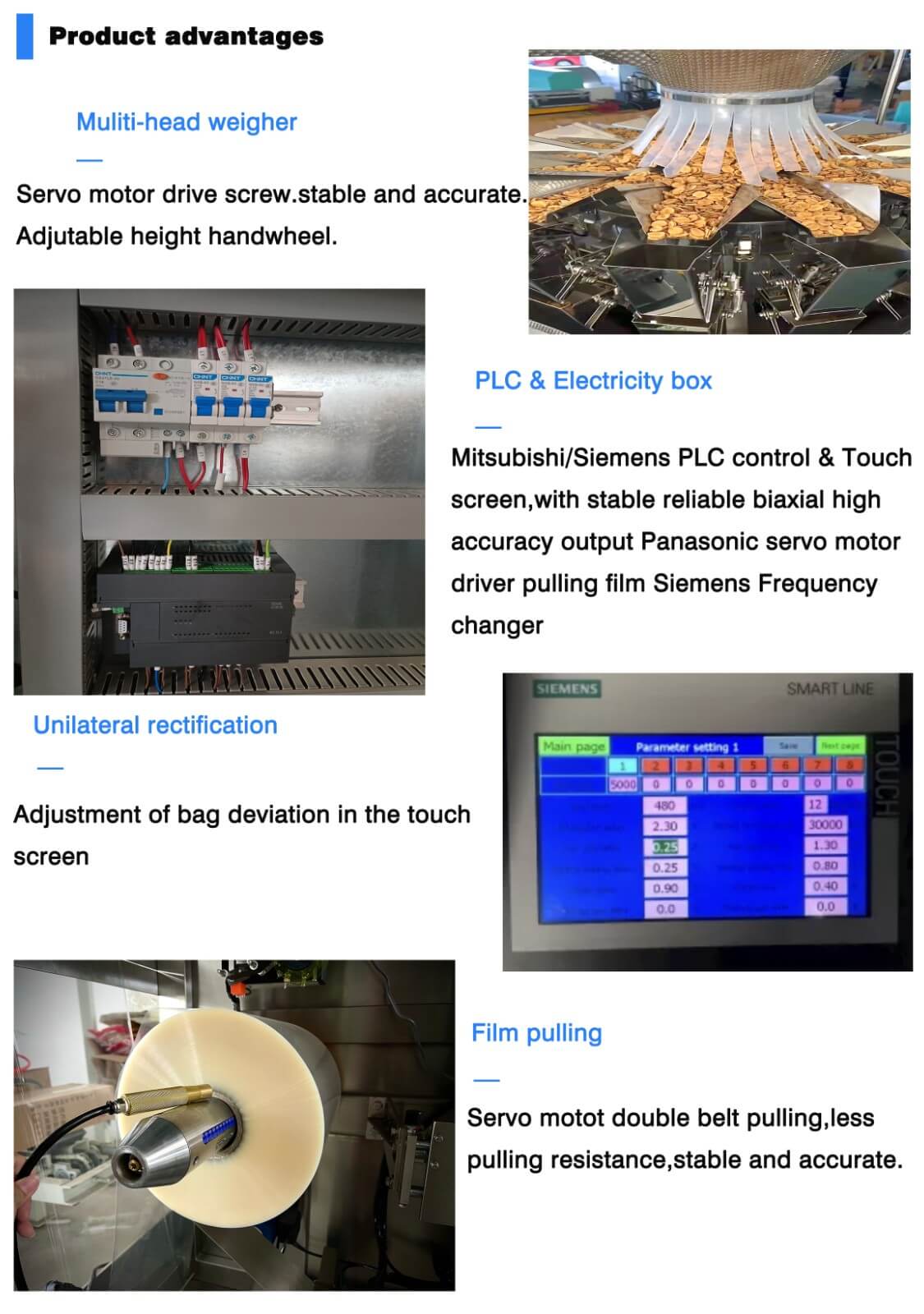

Details

Nut Packaging Machines

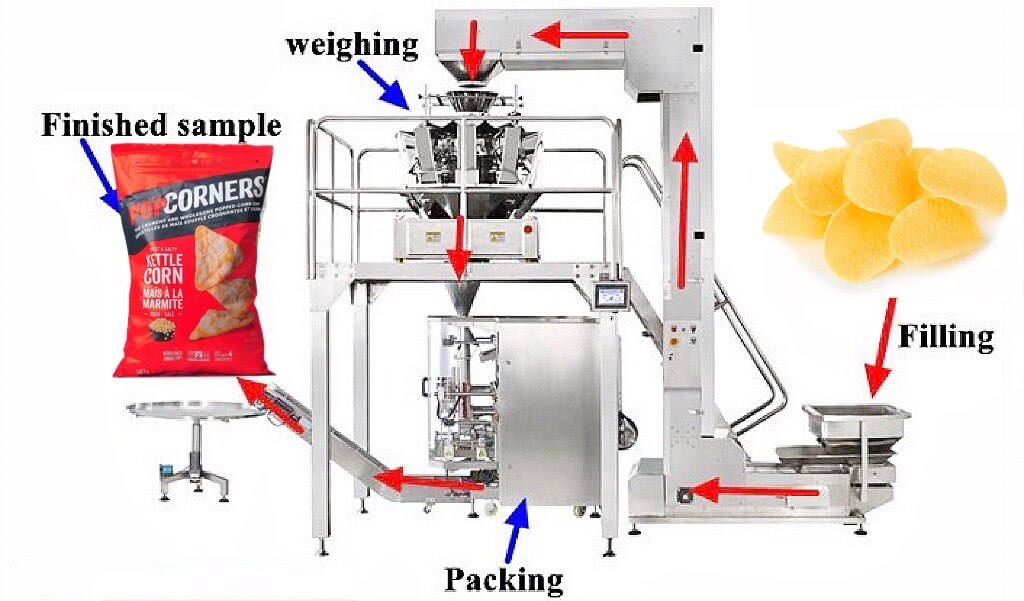

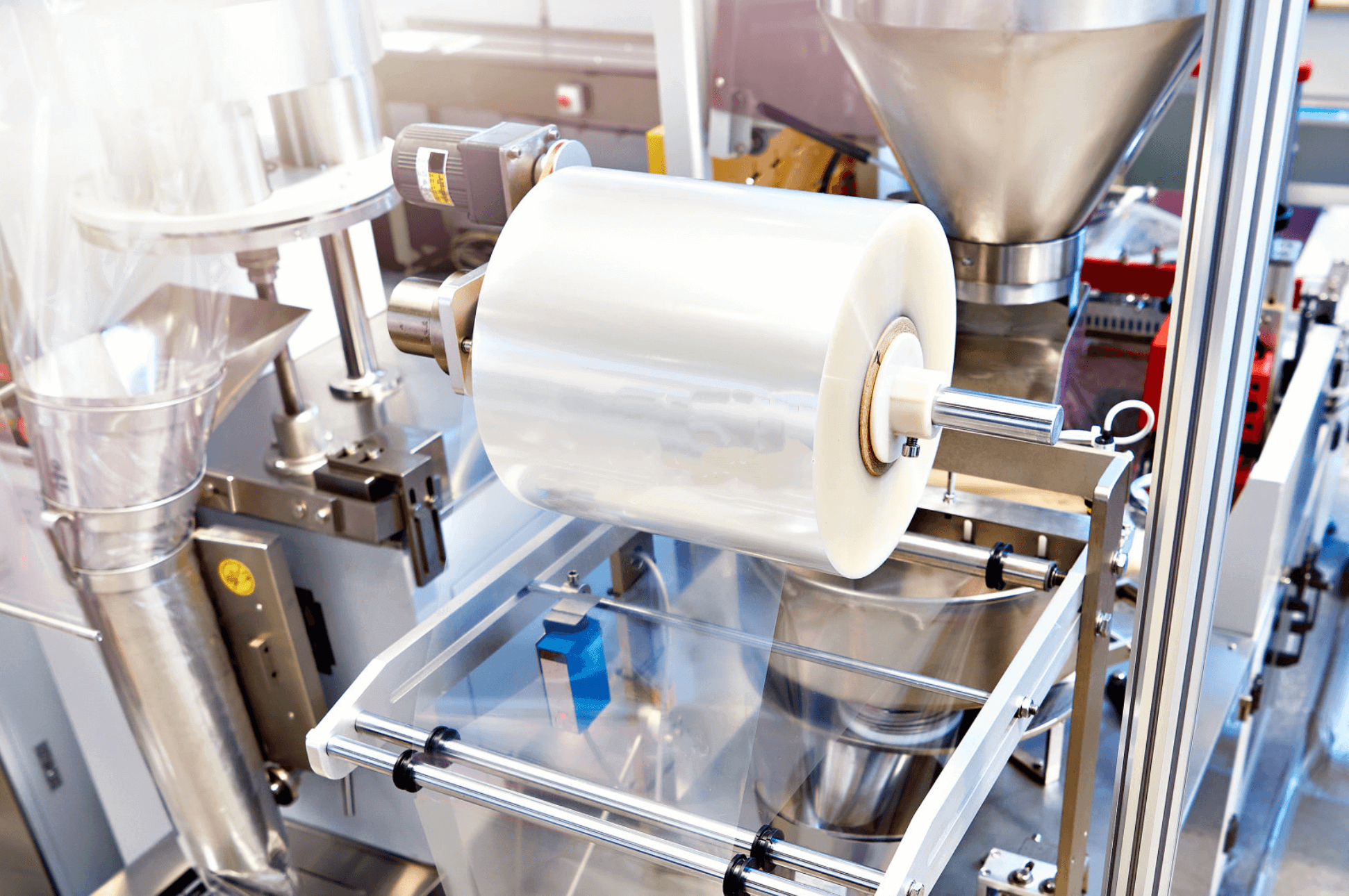

The nuts packing machine is the fully automatic dry fruits packing machine. The machine is able to dose and filling the dry fruits into the pouch which is the machine-made from the film, then sealing and cut. High precise and fast.

You only need to add the dry fruits into the feeder and set the volume per pouch on the touch screen, put the roll film on the machine, then the machine will begin working, from powder to one bag, Save cost for you. A lot number printer is an optional device.

Nuts Packing Machine /Dry Fruits Packing Machine

I. Application & Feature

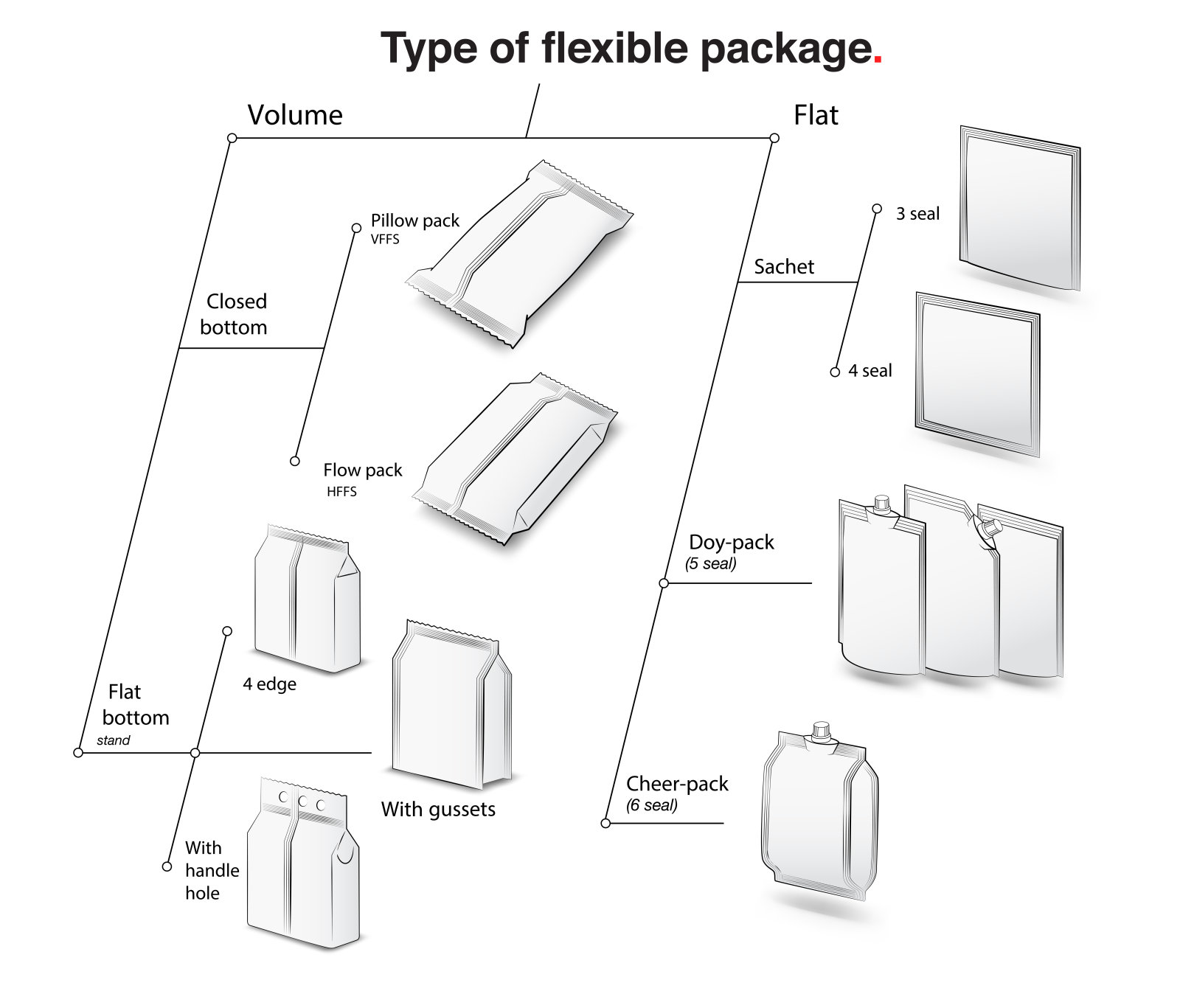

This machine is for filling granule products like candy, nuts, tea, seeds, peanut, chips, popcorn, biscuit, hardware, etc. into all types of pouches, then do sealing for the pouches, such as stand up pouch, zipper pouch, spout pouch, hand pouch, gusset pouch, 3 sides sealed pouch, 4 sides sealed pouch or other type pouches etc.

Firstly put pouches into the hopper by manual, then the machine can automatically suck pouch by vacuum, feed pouch, print date, open pouch & zipper, fill powder.

Equipped with advanced PLC control system from OMRON, digital temperature controller from OMRON, other electric parts from SCHNDIER, etc.

The complete machines are made by stainless steel 304 materials and non-stop for more empty pouches added.

1) Reduce 4-10 workers in one packaging line to bring down the costs of production and management. It takes 6-8 months to recover the cost.

2) Improve the finished product quality. The product meets uniform standards from appearance and packaging quality.

3) Reduce the defective rate. The finished product rate can reach 99.5% or more and avoid the waste of manual packaging.

4) Improve hygiene standards. The packaging process has no direct contact with humans and avoids contamination.

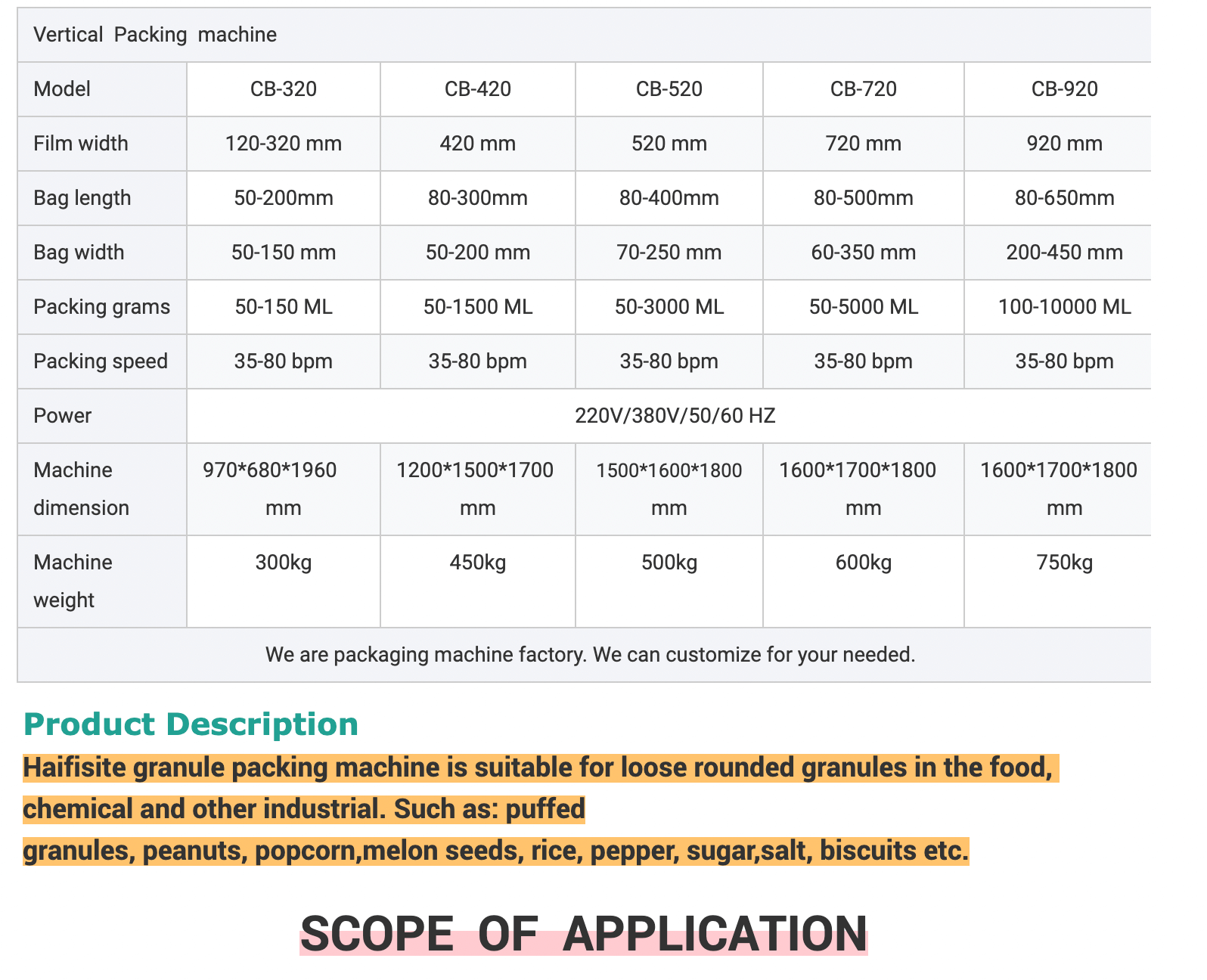

Vertical Packing Machine

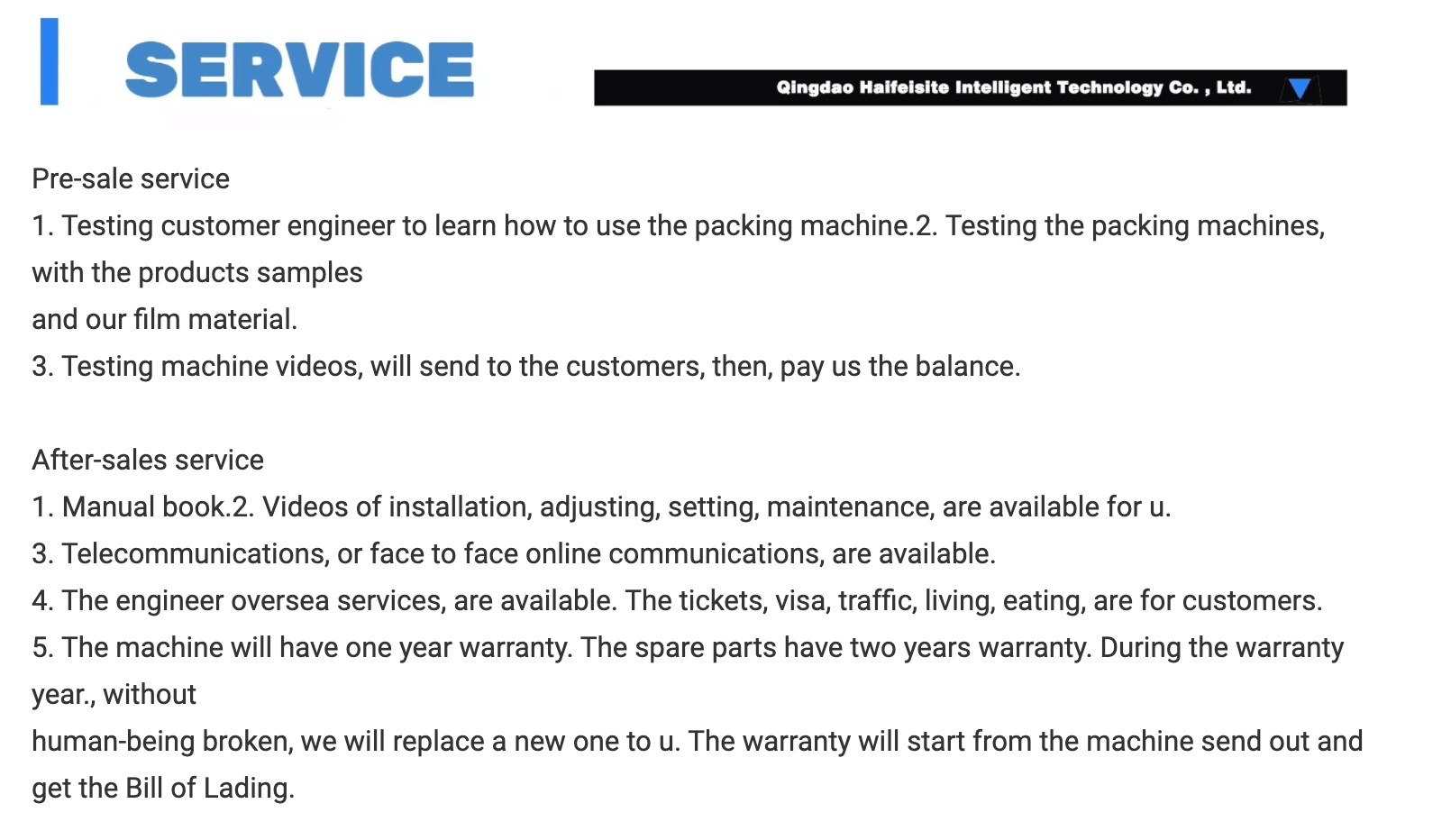

Optional Device

1. Printer(ink jet, Thermal transfer, color ribbon date printer)

2. Nitrogen device

3. Labeling device