Spaghetti Production And Packaging Solutions

Hfirst Spaghetti production line and packaging machines has 20 years of research and development and manufacturing experience in China. Applicable to bulk strip-shaped materials such as: dry noodles, Spaghetti automatic making, weighing and packaging. Fully automatic and high-precision weighing and high-speed packaging, controlled by a highly intelligent system, with strong stability and stainless steel material meeting food grade standards. The 8000 square meter production and manufacturing workshop has a R&D technical team of over 20 people and over 100 employees. We have CE and ISO9001 certifications, over 30 national technology patents, and have led the development of Chinese national technical standards for noodle packaging.Products are sold to countries such as the United States, North America, South America, Africa, and Europe.

Details

Spaghetti Production And Packaging Solutions

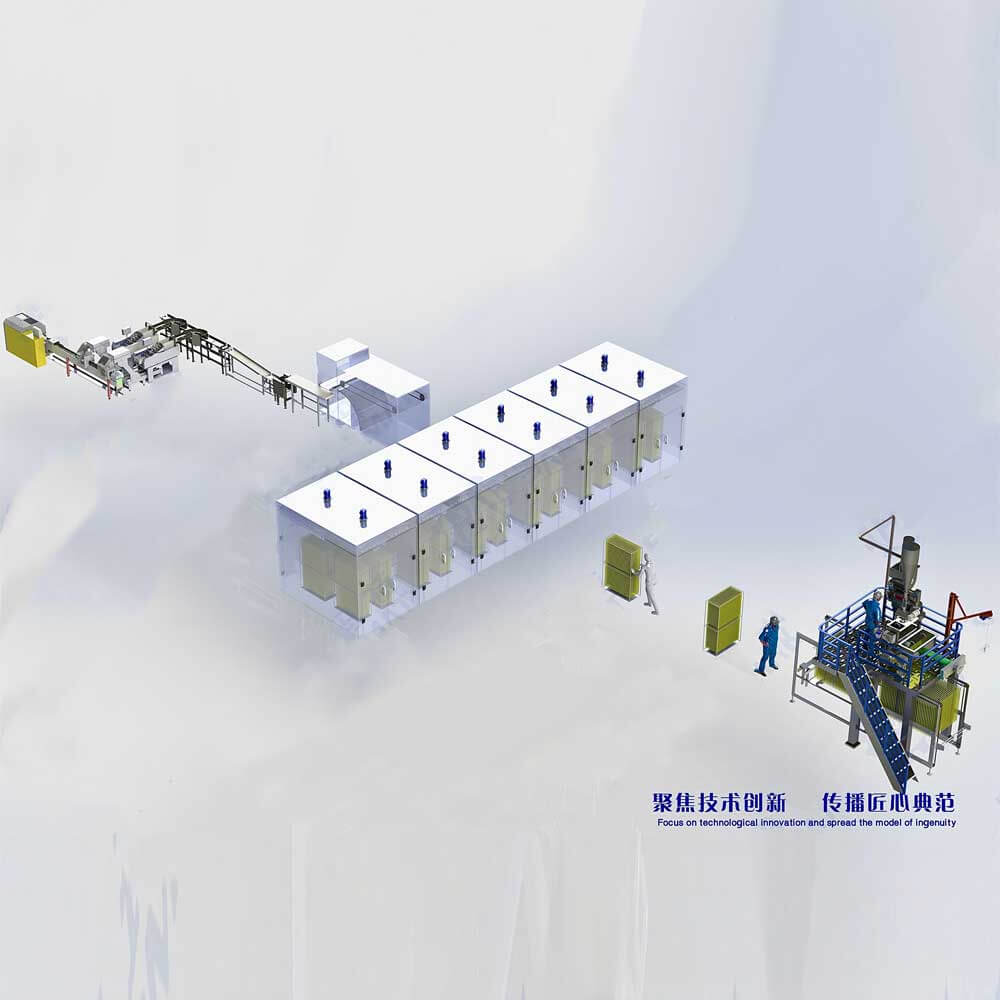

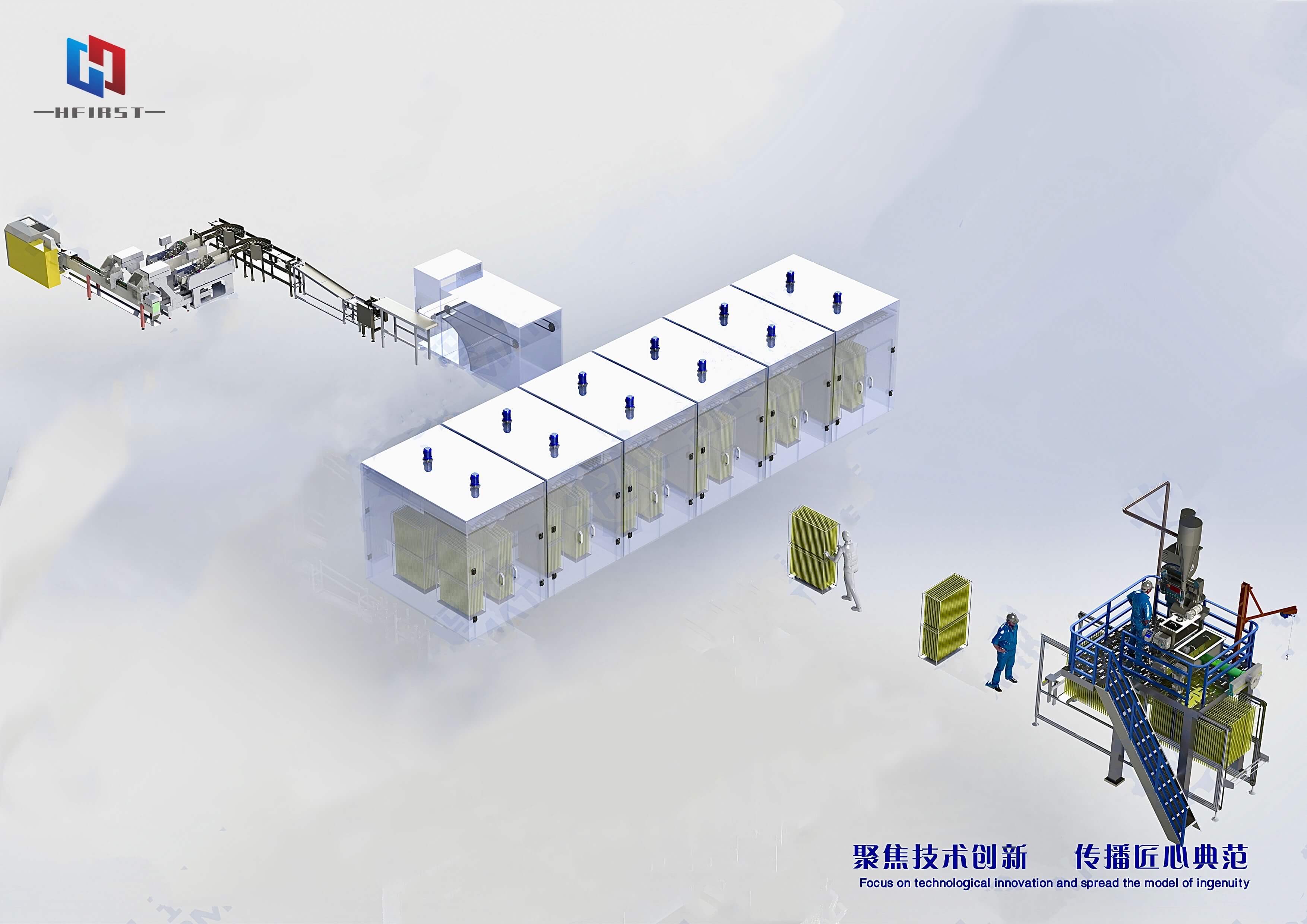

Parmat CQ200 pasta production line, 1-2 people can complete the production line operation. 200KG - 500KG/H production capacity. The products are all 304 stainless steel and Q235 material

Using durum wheat flour as raw material, put it into a vertical high-speed mixer in a precise proportion, add appropriate amount of water, and automatically and fully mix it evenly → Automatically transport the raw materials to the automatic vacuum dough mixer → The mixed flour enters the vacuum mixer for stirring → Automatic vacuum High vacuum extrusion of extruder → Filament automatic conveyor → automatic hanging rod elevator → spaghetti automatic shearing machine → finished product is filled with cart and pushed into warehouse

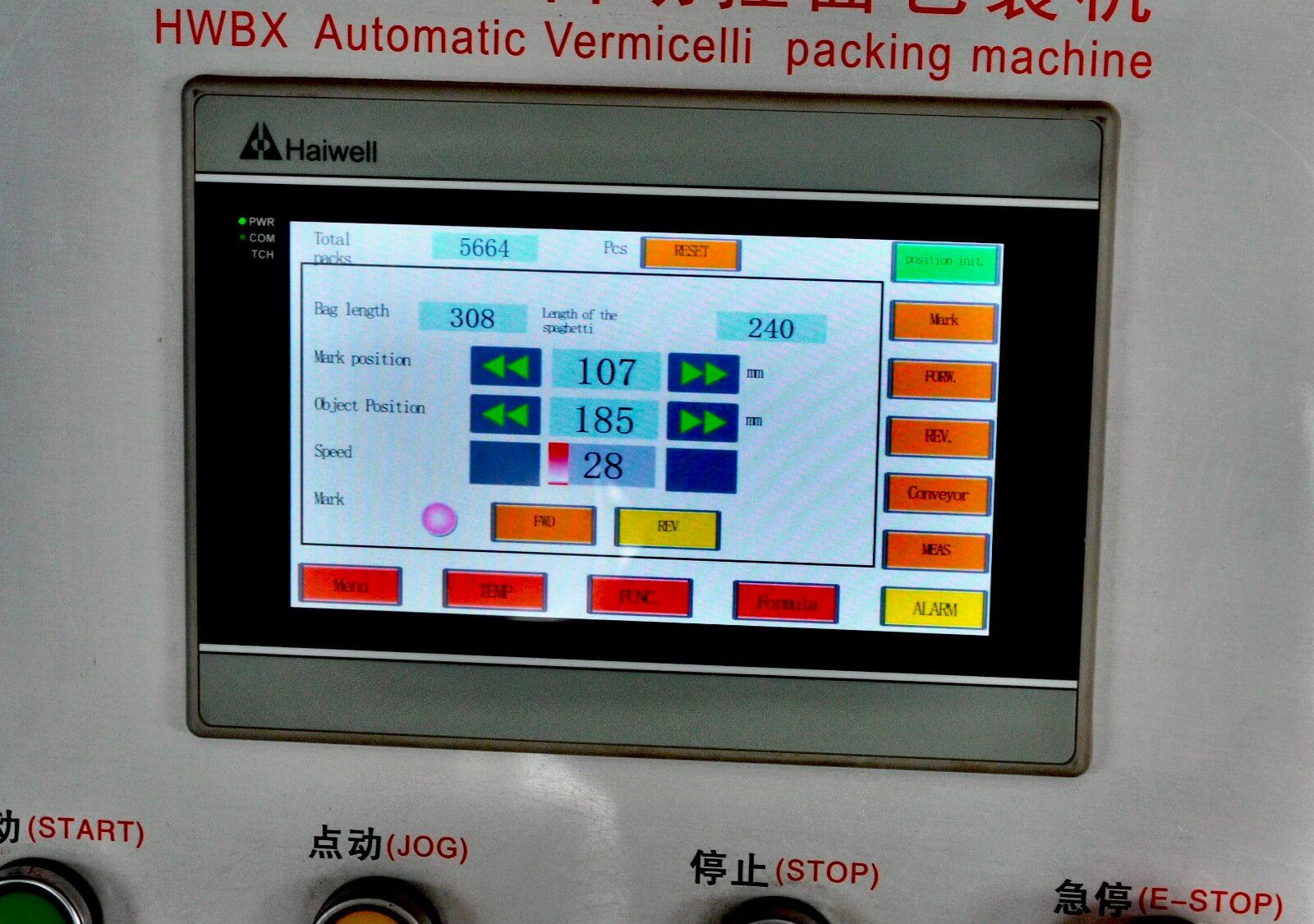

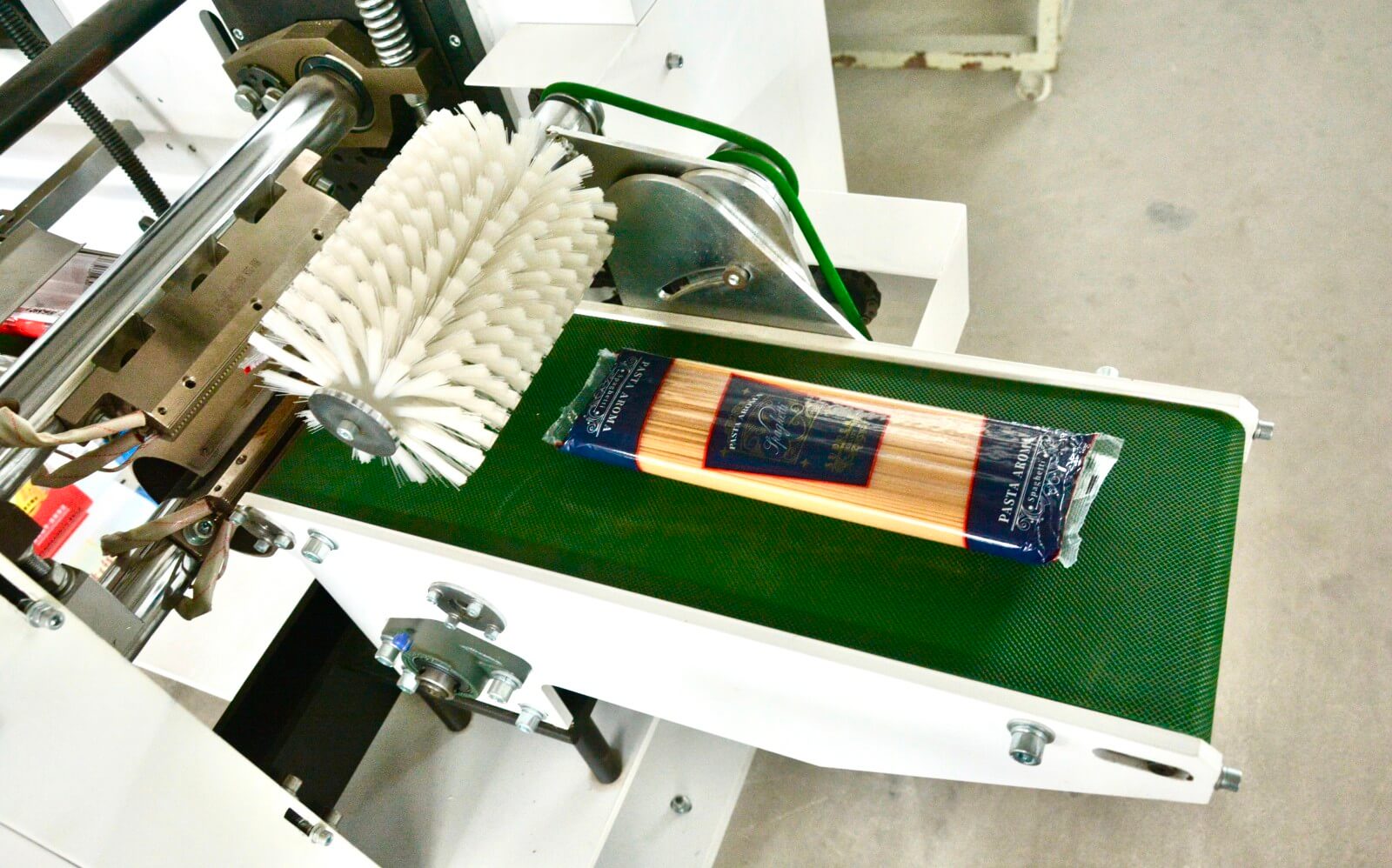

The packaging production line is connected to the cutting machine to complete automatic weighing and packaging.

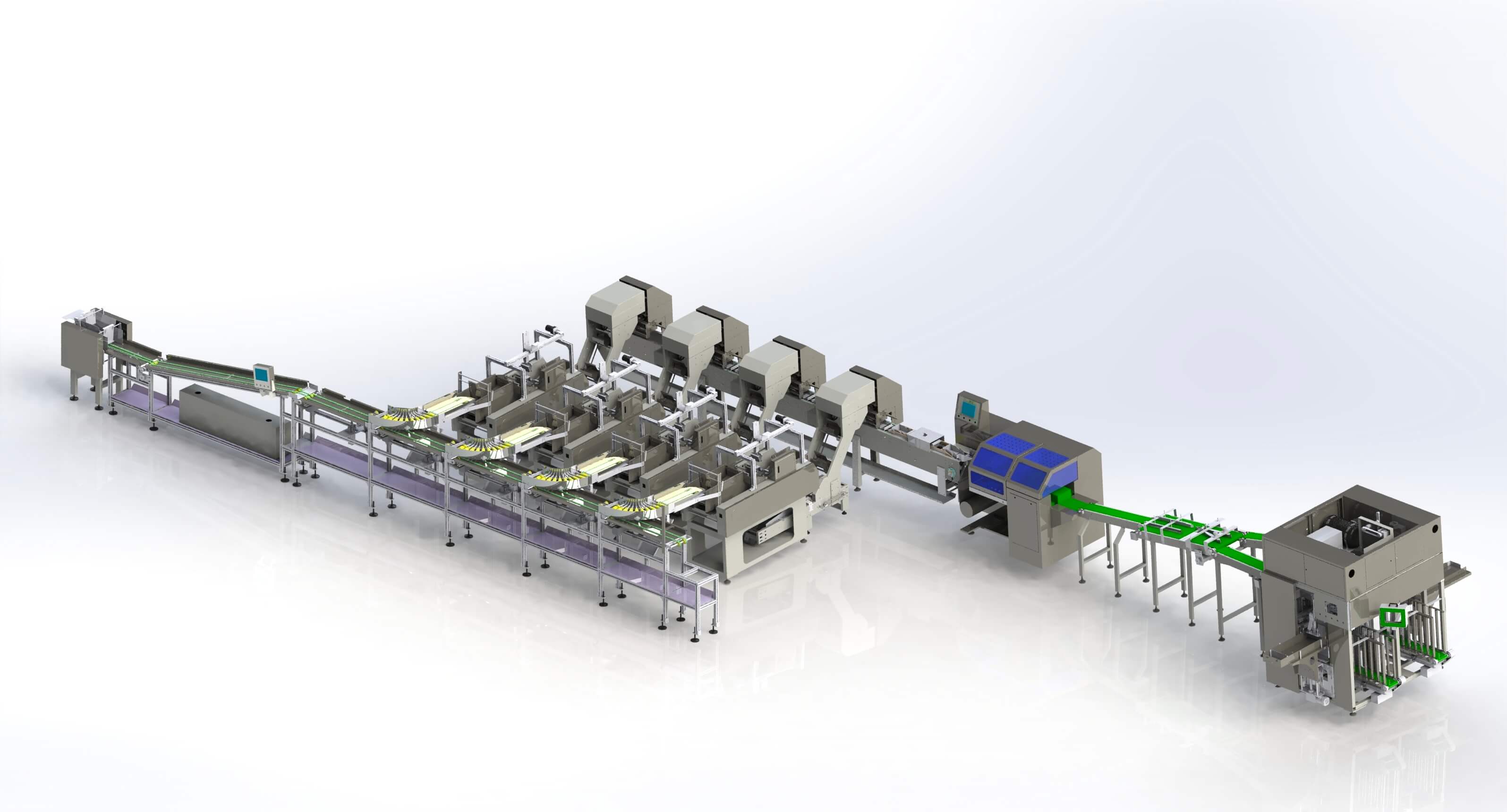

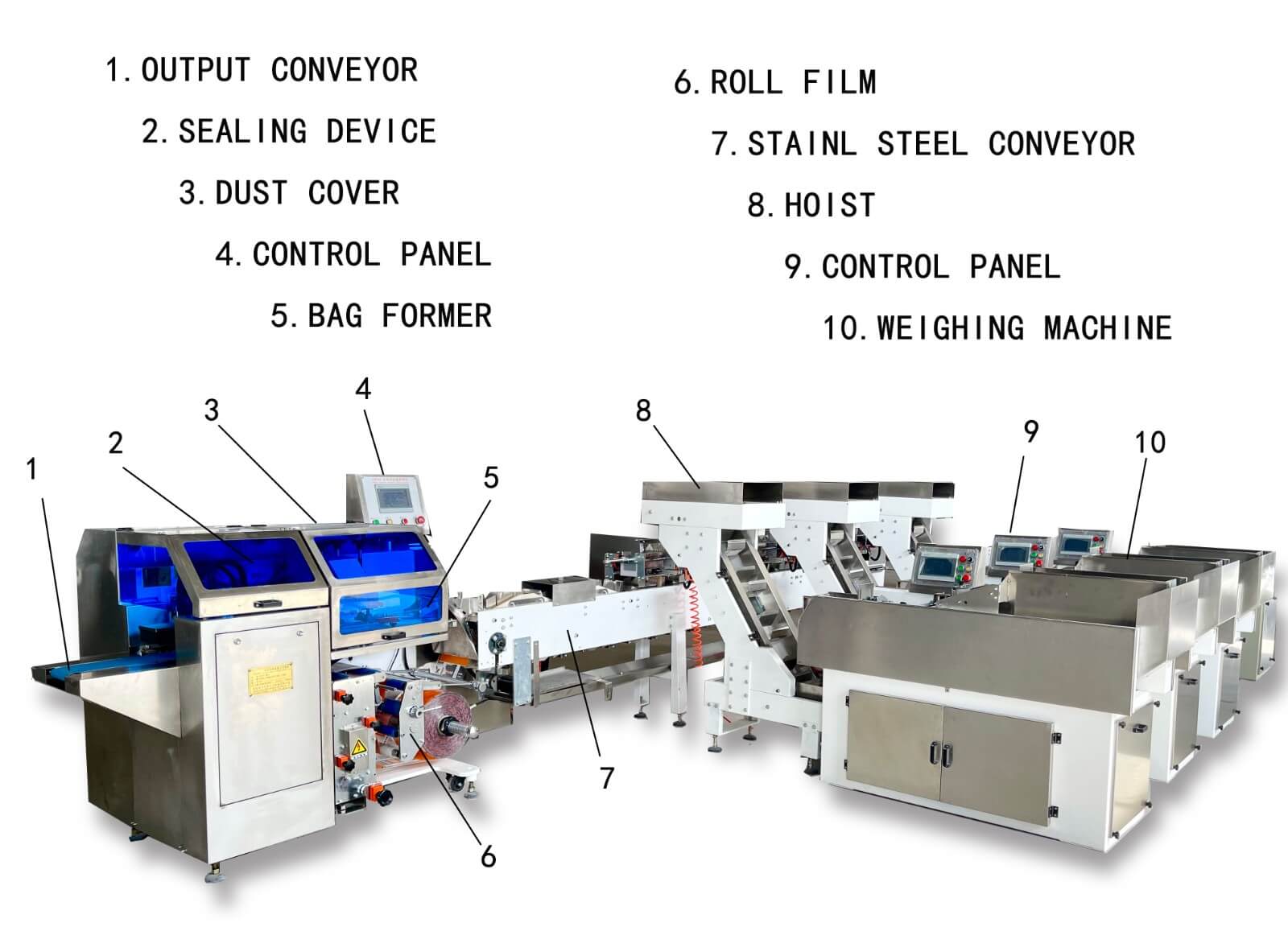

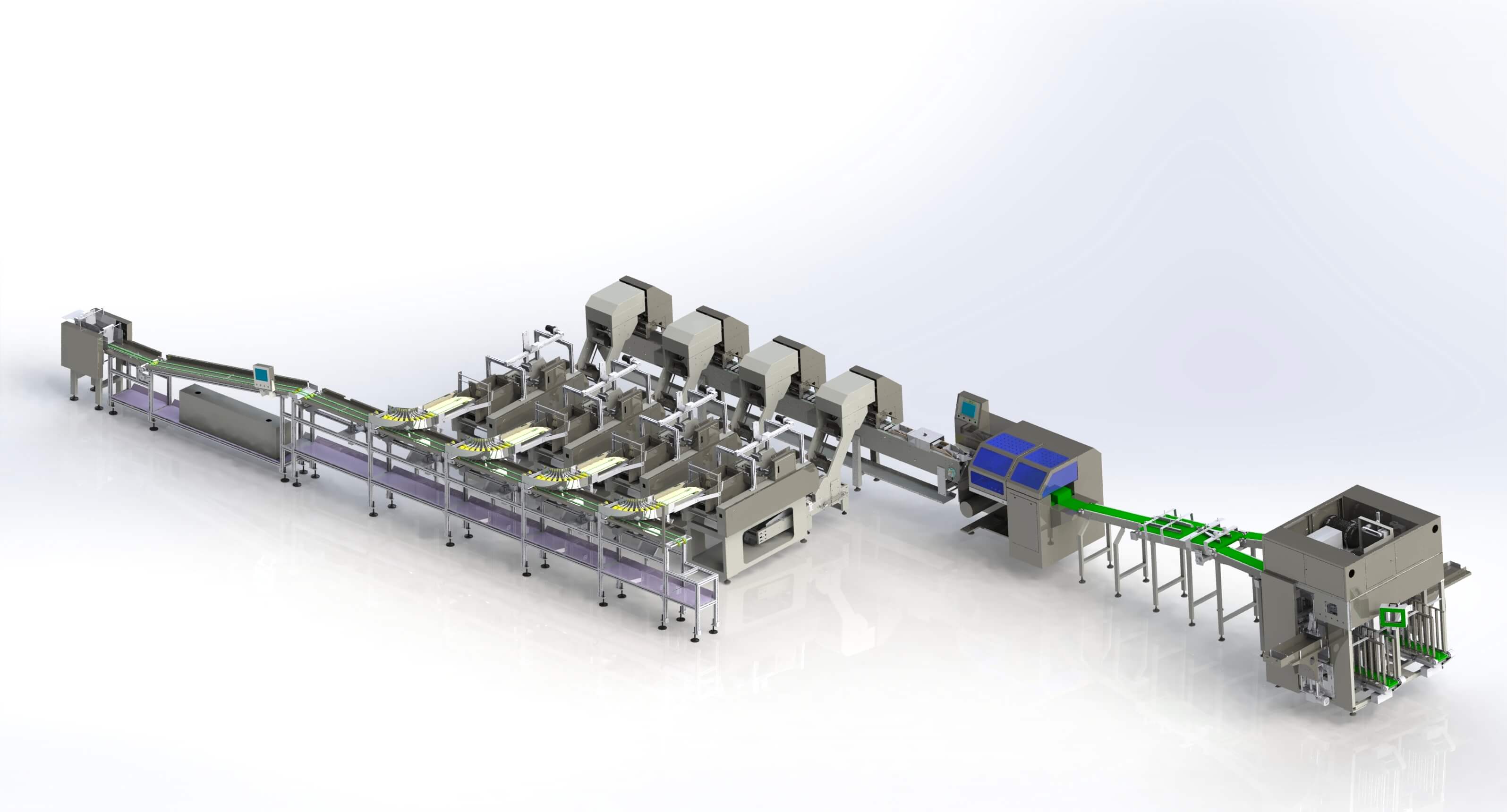

Contains: Weighing machine multiple sets, strapping machine multiple sets, multiple sets of the conveyor, the conveyor line, a set of material, three servo packaging machine 1 sets, 1 sets of centralized control system.

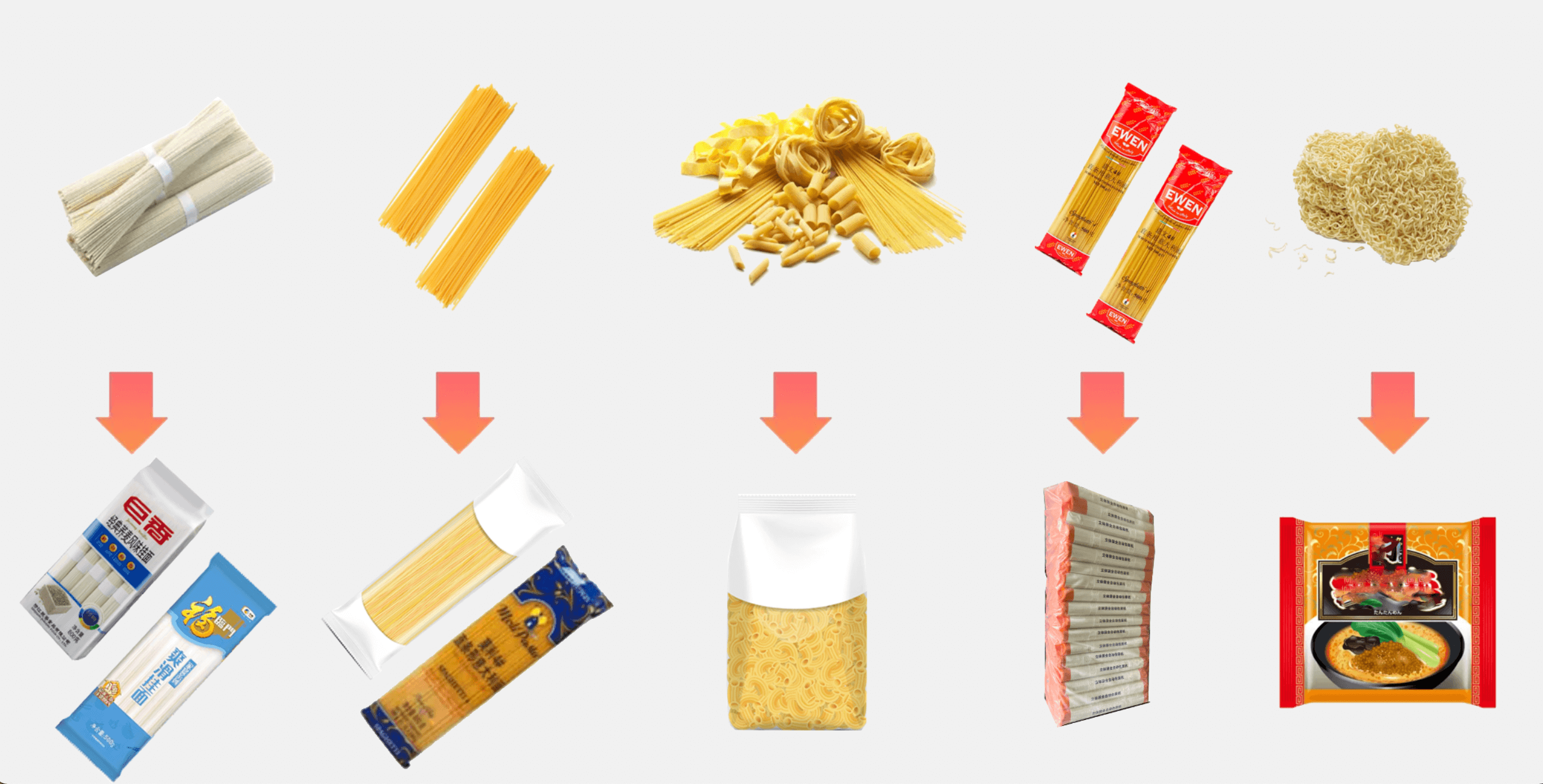

Applications: The complete of equipment for bulk noodles, pasta weighing strapping automatic counting and packing: the realization of the full automation of bulk fine dried noodles,pasta,automatic weighing, bunding, hoisting, feeding, counting and automatic bag forming packaging.