Product recommendation

In today's fast-paced world, convenience and efficiency have become paramount in every aspect of our lives, including food production. The noodle production line is a game-changer in the pasta manufacturing industry, streamlining the process and delivering high-quality noodles to our plates in record time. This advanced technology has transformed traditional noodle-making methods, allowing manufacturers to meet the ever-increasing demand for noodles worldwide.

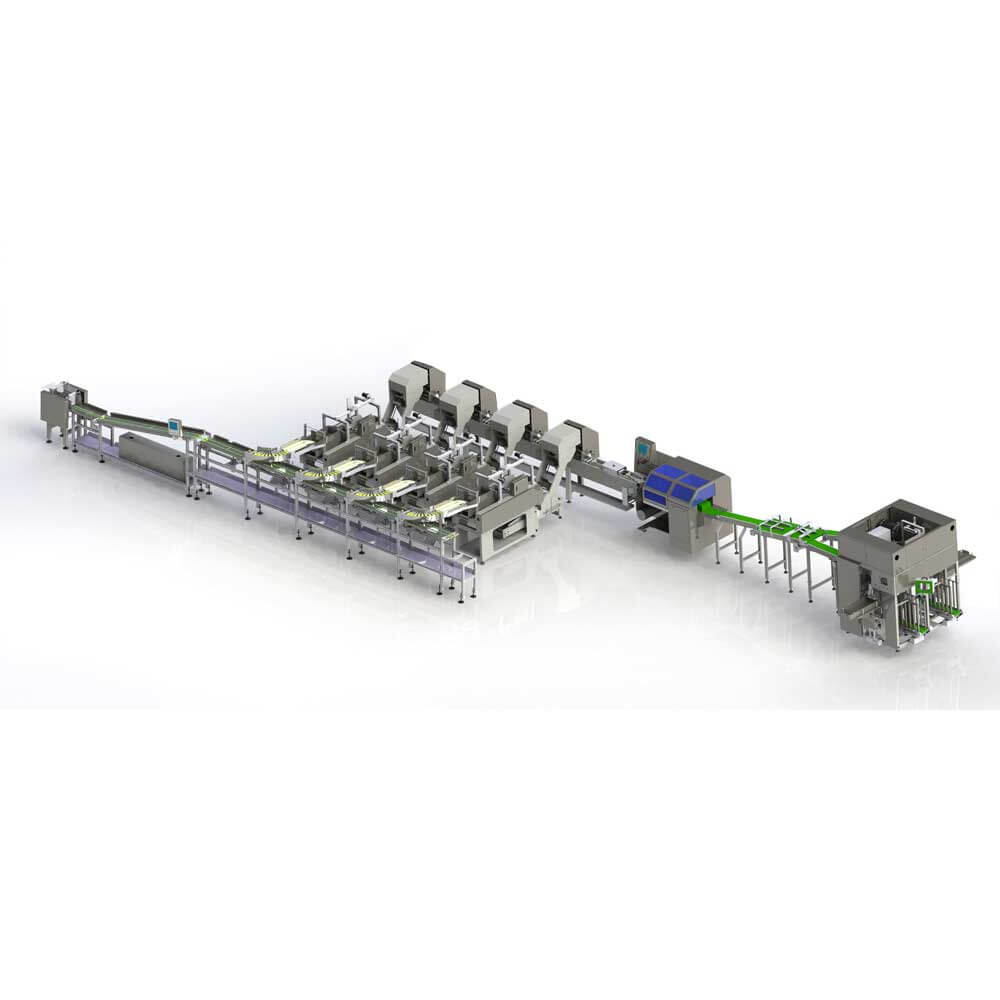

The noodle production line is a fully automated system that handles every step of the noodle manufacturing process, from mixing the ingredients to packaging the final product. This innovative technology has proven to be a game-changer for noodle manufacturers, enhancing productivity, reducing labor costs, and ensuring consistent quality.

One of the key advantages of the noodle production line is its ability to handle large-scale production efficiently. Traditional noodle-making methods required manual labor, making it difficult to meet the growing demand for noodles. With the automated production line, manufacturers can produce a vast quantity of noodles in a shorter time frame, ensuring a steady supply to meet consumer needs.

Moreover, the noodle production line guarantees consistent quality throughout the manufacturing process. By automating the mixing, kneading, and cutting processes, manufacturers can maintain precise control over the ingredients and ensure uniformity in taste, texture, and shape. This consistency is crucial for building a loyal customer base and maintaining the reputation of the brand.

Efficiency is another significant advantage of the noodle production line. The automated system minimizes human error and maximizes production output. It eliminates the need for manual labor-intensive tasks, such as dough rolling and cutting, which not only saves time but also reduces the risk of contamination. Additionally, the production line can be easily adjusted to accommodate various noodle types and sizes, providing manufacturers with flexibility and adaptability.

Furthermore, the noodle production line promotes sustainability in the pasta manufacturing industry. With the increasing global focus on environmental conservation, manufacturers are under pressure to adopt eco-friendly practices. The automated system optimizes energy consumption, reducing waste and minimizing the carbon footprint. Additionally, the production line's efficient use of water resources contributes to sustainable manufacturing practices.

From a marketing perspective, the noodle production line offers manufacturers a competitive edge. By highlighting the use of advanced technology and the resulting benefits, companies can position themselves as leaders in the industry. Consumers are increasingly seeking convenience and quality, and the production line enables manufacturers to meet these demands effectively.

In conclusion, the noodle production line has revolutionized the pasta manufacturing industry. Its ability to handle large-scale production, ensure consistent quality, and promote sustainability makes it an invaluable asset for noodle manufacturers. As consumer demand for noodles continues to rise, companies that embrace this advanced technology will undoubtedly thrive in the competitive market. By leveraging the advantages of the noodle production line, manufacturers can cater to the evolving needs of consumers, solidify their brand reputation, and drive growth in the industry.

Please visit product page for more information

-

Noodle Production And Packaging Solutions

Noodle Production And Packaging Solutions is automatically completed from flour to finished product, with simple operation, novel design, moderate output, small footprint, low investment and quick results. This production line can produce round or square instant noodles. The corrugated instant noodles produced have short re-hydration time, good elasticity, smoothness and transparency, and are comparable to large-scale equipment popular in the market. Hfirst noodle production line and packaging machine has 20 years of research and development and manufacturing experience in China. Applicable to bulk strip-shaped materials such as: dry noodles, Spaghetti,stick noodles automatic making, dry, weighing and packaging. Fully automatic and high-precision weighing and high-speed packaging, controlled by a highly intelligent system, with strong stability and stainless steel material meeting food grade standards. The 8000 square meter production and manufacturing workshop has a R&D technical team of over 20 people and over 100 employees. We have CE and ISO9001 certifications, over 30 national technology patents, and have led the development of Chinese national technical standards for noodle packaging.Products are sold to countries such as the United States, North America, South America, Africa, and Europe.

More

-

- Celebrate the Mid-Autumn Festival with Quality and Tradition: Discover Our Noodle Packaging Solutions

- HARVEST-Noodle Packaging Machine Manufacturer Ready for the 135th Canton Fair

- Preparation Work for HARVEST to Participate in the 135th Spring Canton Fair

- South African customers will visit the factory soon